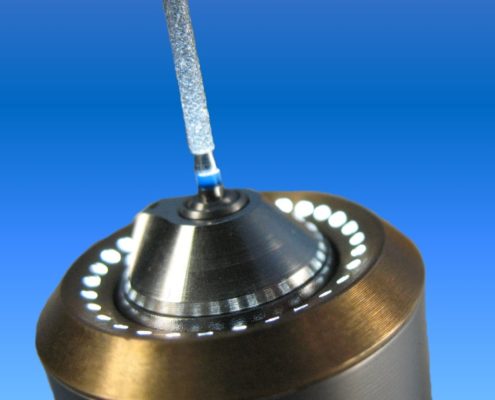

CNC turning technology

We use our CNC-controlled lathes to manufacture our high-precision titanium medical products.

We also produce series and individual parts for manufacturers from other industries.

Metallic materials, plastics

Bar capacity: max. Ø 18 mm – Rod length: max. 3.6 m

In addition, conventional turning is also possible

Materials: all metallic materials, plastics

Workpiece Ø: max. 125 mm – Turning length: max. 300 mm